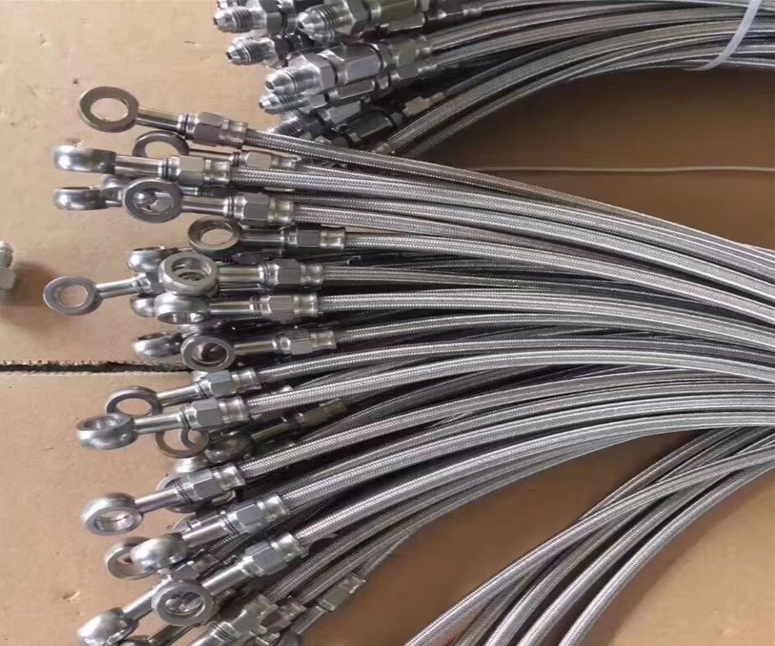

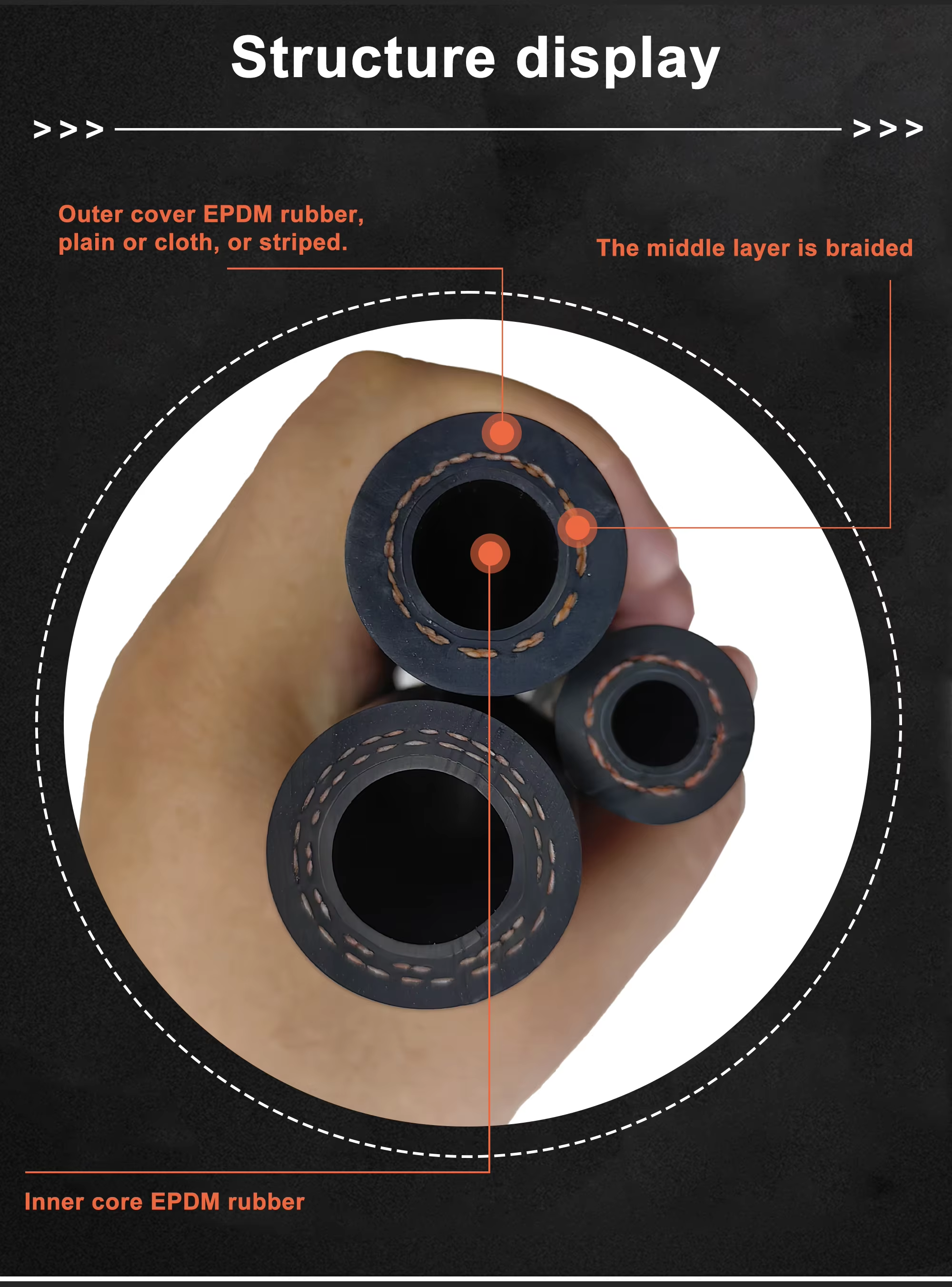

The brake hose manufacturing process involves sequential precision operations that transform raw materials into finished safety-critical components through controlled procedures with rigorous quality verification. Production begins with material preparation including compounding of synthetic rubber formulations like EPDM or SBR with specific additives for fluid resistance and environmental durability, or preparation of thermoplastic compounds like nylon or TPE with optimized mechanical properties. Extrusion operations form the basic hose structure using computer-controlled machines that maintain precise dimensional tolerances for inner diameter and wall thickness, with real-time monitoring systems ensuring consistency throughout production runs. Reinforcement application utilizes specialized braiding machines that weave layers of high-tensile synthetic yarn such as aramid or polyester, or stainless steel wire, in specific patterns with controlled tension to provide structural strength while maintaining flexibility. Vulcanization processes for rubber hoses employ continuous autoclave systems or individual molding that apply specific temperature profiles between 150℃-180℃ under pressure to achieve optimal cross-linking and material properties. For thermoplastic hoses, additional processing may include cross-linking through electron beam irradiation or chemical methods to enhance temperature resistance and durability. Cutting operations use precision automated equipment that creates clean square ends essential for proper fitting attachment, with length verification systems ensuring compliance with specified tolerances. Fitting attachment represents a critical phase utilizing hydraulic crimping machines with calibrated dies that apply specific compression forces to create permanent connections between hose ends and metal fittings, with process monitoring systems documenting force application profiles for each assembly. Marking operations apply permanent identification including manufacturer codes, date stamps, and compliance markings using indentation wheels or laser etching systems. Final inspection includes 100% pressure testing, visual examination for surface defects, and dimensional verification, with statistical sample testing for comprehensive validation including impulse cycling, tensile strength, and environmental resistance. Our manufacturing philosophy emphasizes process control and continuous improvement through advanced production technology and comprehensive quality management systems. For detailed information regarding our brake hose manufacturing capabilities and process technologies, we invite potential partners to consult with our engineering team for technical documentation and facility overviews.