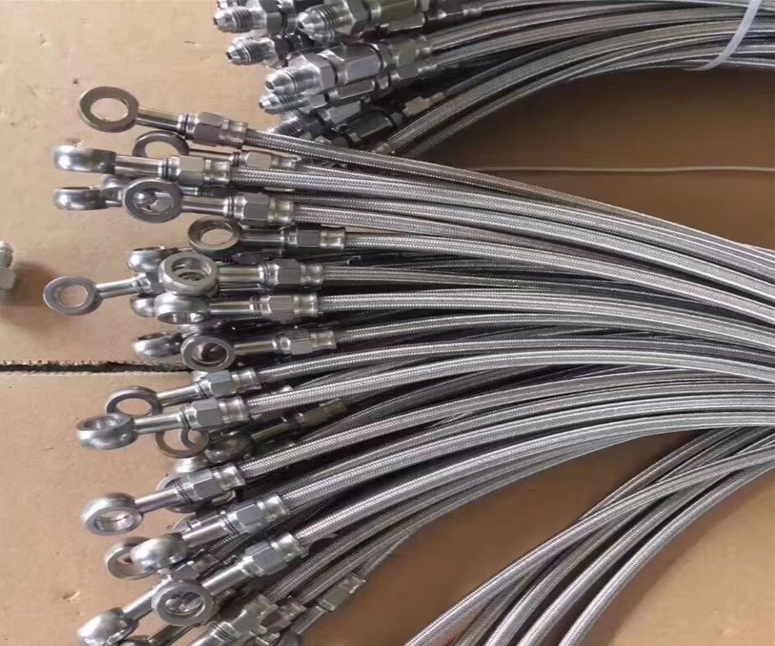

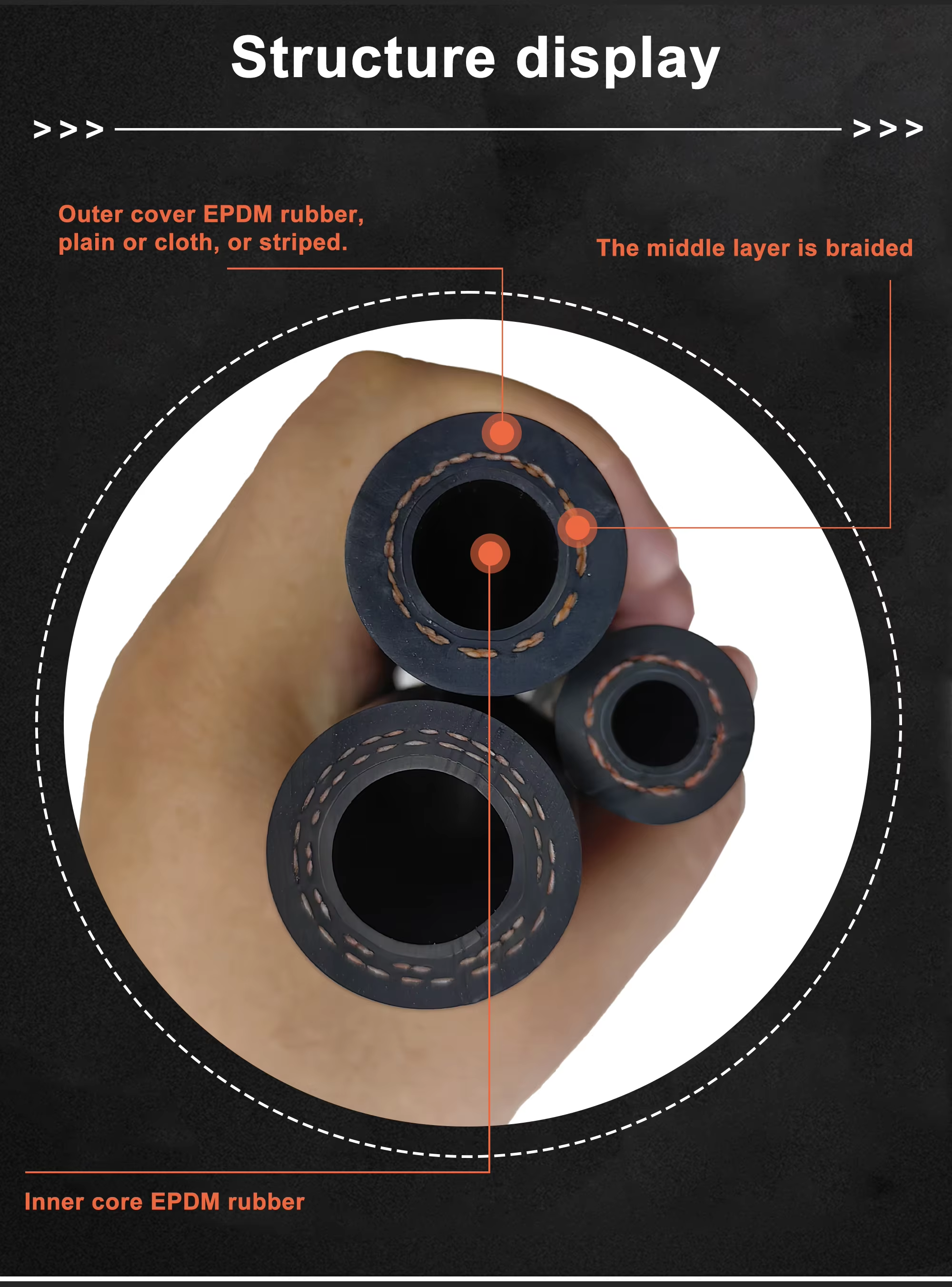

Car brake hoses represent flexible hydraulic conduits that transmit braking pressure from the vehicle's fixed brake lines to the wheel cylinders or calipers, accommodating suspension movement and steering articulation while maintaining system integrity. These safety-critical components feature multi-layer construction typically comprising an inner tube manufactured from synthetic rubber compounds like EPDM or SBR specifically formulated for compatibility with DOT 3, DOT 4, and DOT 5.1 brake fluids, intermediate reinforcement layers of high-tensile synthetic yarn or stainless steel braiding providing structural strength and burst resistance, and an external cover resistant to abrasion, ozone, ultraviolet radiation, and environmental contaminants. Performance specifications include minimum burst pressure requirements typically exceeding 2,000 PSI to handle system operating pressures, impulse testing validation through 1-2 million pressure cycles at elevated temperatures up to 120℃ , and flexibility maintenance across extreme temperatures from -40℃ to 100℃. Design variations address specific vehicle requirements including different hose lengths for various wheelbase and suspension configurations, varying connection types including inverted flare, metric bubble flare, and O-ring face seal fittings, and specialized constructions for vehicles equipped with anti-lock braking systems or electronic stability control. Material technology continues evolving with advanced thermoplastic formulations offering reduced permeability, enhanced durability, and improved environmental resistance compared to traditional rubber compounds. A documented case from automotive engineering demonstrated how modern brake hose designs maintained structural integrity after equivalent of 15 years of simulated service including exposure to road salts, ultraviolet radiation, and mechanical fatigue from suspension cycling. Installation protocols emphasize proper routing with adequate clearances from moving components and heat sources, correct positioning of mounting brackets to prevent stress concentration, and careful torque application during fitting installation to prevent damage to sealing surfaces. Our product range includes comprehensive coverage of passenger vehicle applications with particular attention to OEM specifications for dimensional accuracy, connection types, and performance characteristics. For technical specifications, application guides, and performance data regarding car brake hoses, we provide detailed documentation through our technical resources and welcome specific vehicle application inquiries.