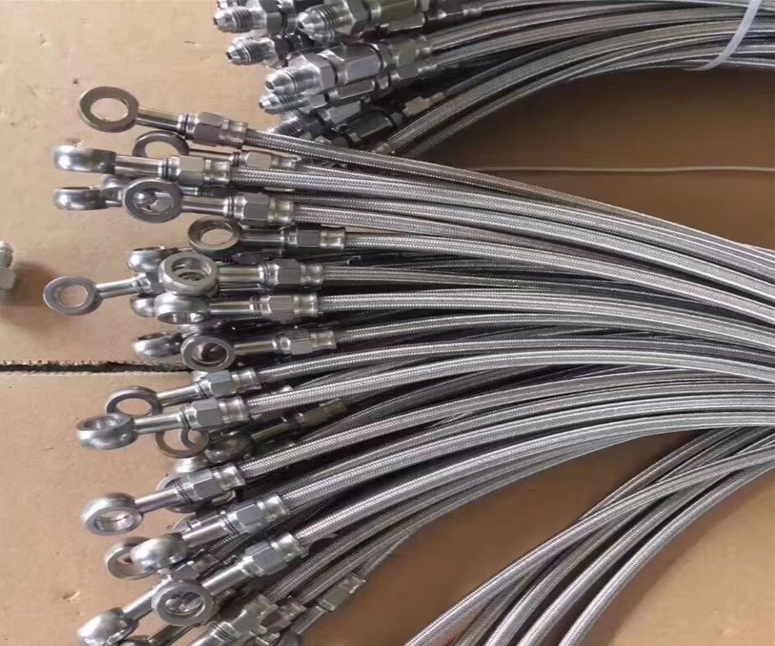

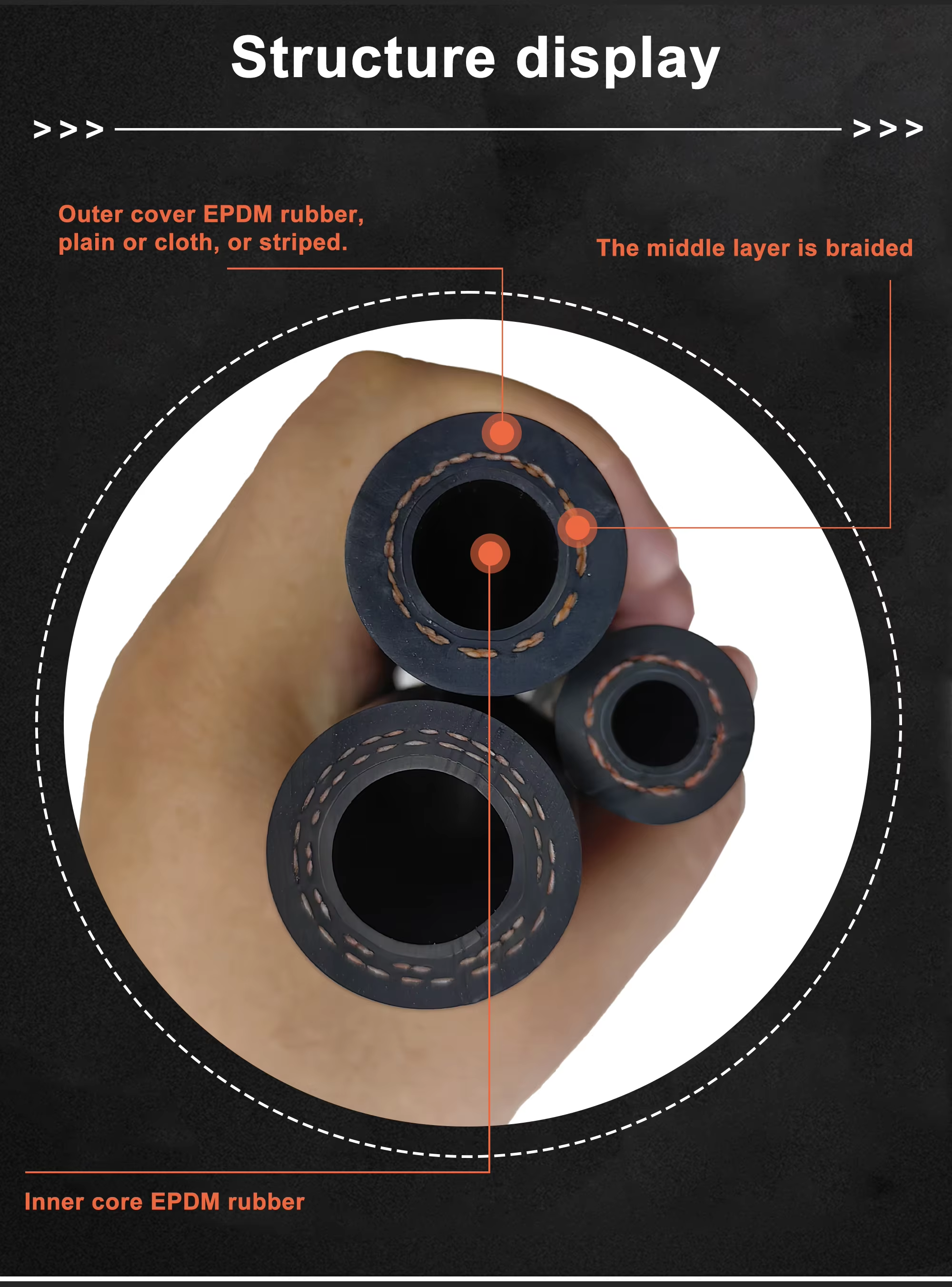

Brake hoses for cars are precisely engineered, flexible hydraulic conduits that form a critical link within the vehicle's braking system. Their primary function is to reliably transmit hydraulic pressure from the master cylinder and fixed brake lines on the vehicle's body to the brake calipers or wheel cylinders located on the moving suspension and steering assemblies. This role demands that the hoses maintain absolute hydraulic integrity and consistent internal diameter under pressure while simultaneously accommodating the full range of suspension travel, steering articulation, and engine movement without fatigue, kinking, or abrasion. The construction of a modern automotive brake hose is a multi-layer marvel of engineering. It typically begins with an inner tube manufactured from synthetic rubber compounds such as EPDM (Ethylene Propylene Diene Monomer) or SBR (Styrene-Butadiene Rubber), specifically formulated for exceptional compatibility with modern glycol-ether-based brake fluids (DOT 3, DOT 4, DOT 5.1) to prevent swelling, softening, or degradation. Surrounding this inner tube are one or more reinforcement layers, which are crucial for containing high pressure. These layers consist of braided high-tensile synthetic yarn, like polyester or aramid, or sometimes spirally wound or braided stainless steel wire, providing the necessary tensile strength and resistance to expansion under pressure. The entire assembly is protected by a durable outer cover, made from a synthetic rubber resistant to abrasion, ozone, ultraviolet radiation, oil, and other environmental contaminants. Rigorous performance specifications govern their manufacture. Minimum burst pressure requirements, often exceeding 2,000 PSI, ensure a significant safety margin over normal system operating pressures. Impulse testing validates long-term durability by subjecting the hose to millions of pressure cycles, typically from zero to a high test pressure, while submerged in heated brake fluid to simulate years of service. Furthermore, the hose must retain its flexibility and function across a wide temperature spectrum, from -40掳C to over 100掳C, ensuring reliable braking in all climates. Design variations are extensive to meet specific vehicle needs. This includes precise hose lengths tailored to different wheelbases and suspension geometries, and a variety of end fitting configurations such as double female, male-female, banjo bolts with crush washers, or metric bubble flare fittings to ensure a perfect seal with the vehicle's hardlines and calipers. Material technology continues to advance, with Thermoplastic (TPE) hoses gaining prominence for their superior performance, including even lower permeability, enhanced durability, and improved resistance to environmental factors, all while complying with stringent international standards like SAE J1401 and FMVSS 106. A documented case from accelerated life testing demonstrated that a contemporary brake hose design could maintain its structural integrity and sealing capability after the equivalent of 15 years of simulated service, which included exposure to corrosive road salts, continuous UV radiation, and millions of cycles of mechanical flexing. Correct installation is paramount for safety and performance. Protocols strictly emphasize proper routing to maintain safe clearances from sharp edges, moving parts, and exhaust components, the correct positioning of any mounting brackets or clamps to prevent stress concentration points, and the careful application of specified torque values during fitting installation to avoid damaging the flared sealing surfaces. Our product portfolio offers comprehensive coverage for passenger vehicle applications, with a particular focus on matching Original Equipment Manufacturer (OEM) specifications for dimensional accuracy, connection types, and performance characteristics to ensure direct, reliable replacement. For detailed technical specifications, application guides, and specific performance data sheets regarding our brake hoses for cars, we provide extensive documentation through our technical support resources and welcome inquiries for any specific vehicle application.