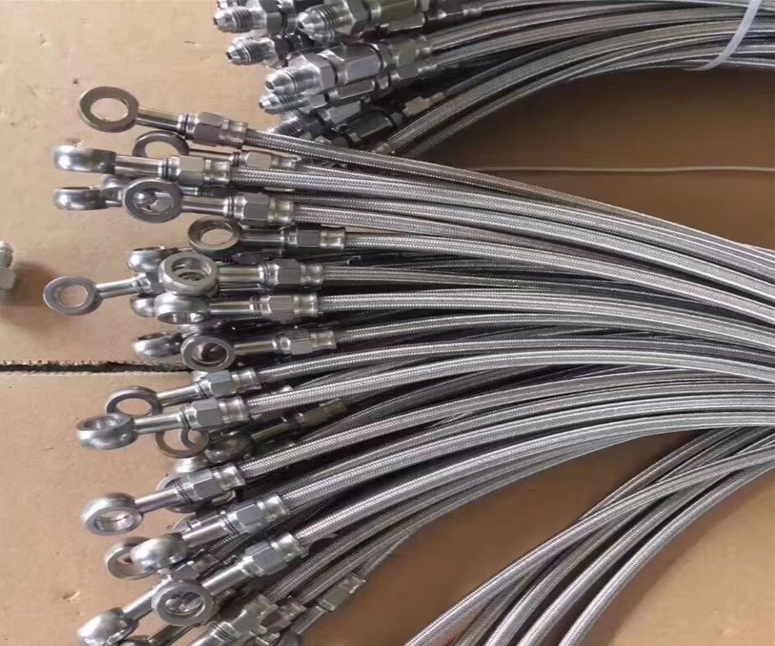

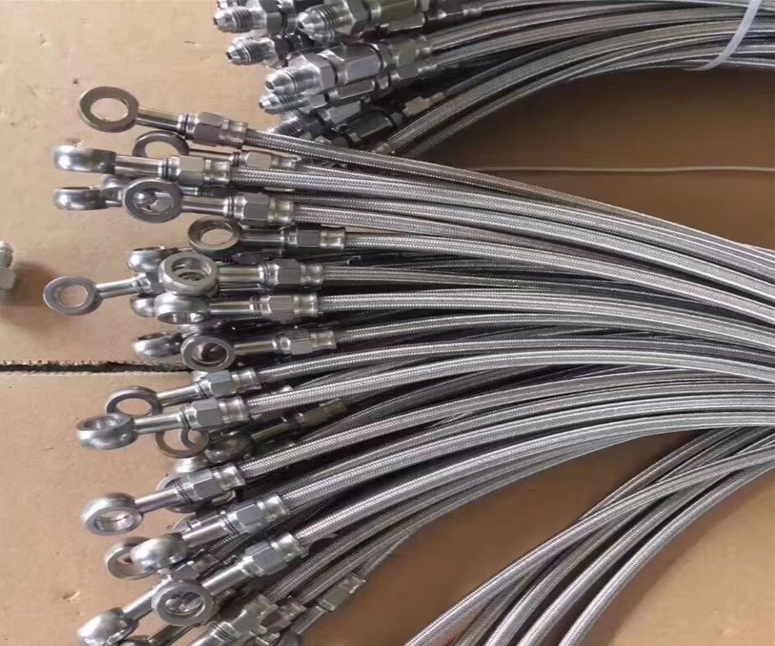

A professional brake hose production line represents an integrated manufacturing system that transforms raw materials into finished safety-critical components through sequential automated processes with rigorous quality control at each stage. The production workflow begins with material preparation including compounding of synthetic rubber compounds or preparation of thermoplastic resins, followed by extrusion processes that form the basic hose structure with precise internal diameter control and wall thickness consistency. Reinforcement application involves specialized braiding machines that apply layers of high-tensile synthetic yarn or stainless steel wire in specific patterns with controlled tension to ensure uniform strength distribution throughout the hose length. The vulcanization process for rubber hoses utilizes continuous or batch curing systems that apply specific time-temperature-pressure parameters to achieve optimal cross-linking and material properties, while thermoplastic versions may undergo additional processing for molecular orientation. Cutting operations employ precision automated saws or blades that create clean square ends essential for proper fitting attachment, with length tolerances typically within 卤1mm for standard applications. Fitting attachment represents a critical phase utilizing calibrated crimping machines that apply predetermined compression forces to create permanent connections between hose ends and metal fittings, with force monitoring and verification systems ensuring consistent results. Marking and identification processes apply permanent labeling including manufacturer identification, date codes, and compliance markings using indentation or specialized printing techniques. Final testing protocols include 100% pressure verification, often using automated test stations that apply specified pressures while monitoring for leakage, with sample testing for comprehensive validation including impulse cycling, tensile strength, and environmental resistance. A documented case from manufacturing optimization demonstrated how automated production lines increased output consistency by 30% while reducing material waste through improved process control and real-time monitoring systems. Our manufacturing facilities incorporate advanced production technology with automated material handling, statistical process control implementation, and comprehensive traceability systems throughout the production sequence. For detailed information regarding our brake hose production capabilities and manufacturing technologies, we invite potential partners to consult with our engineering management for facility overviews and technical specifications.