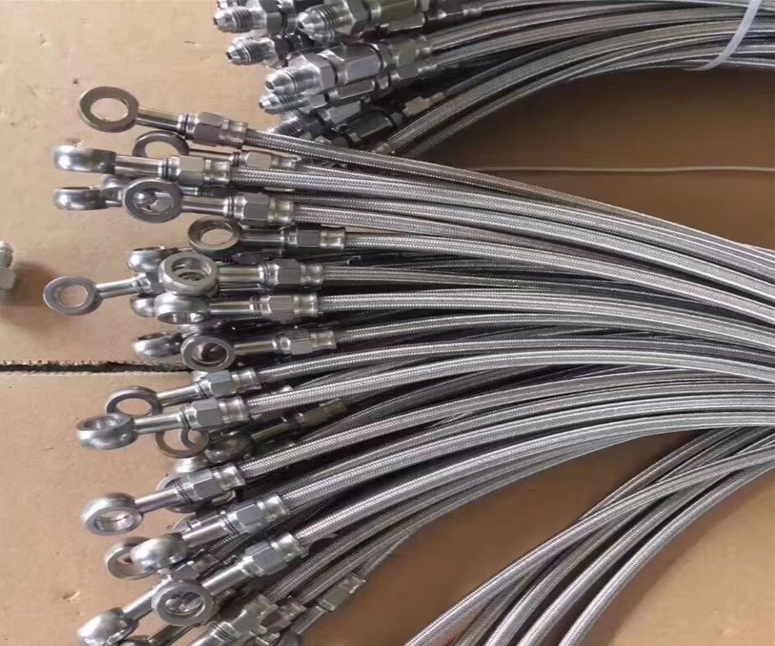

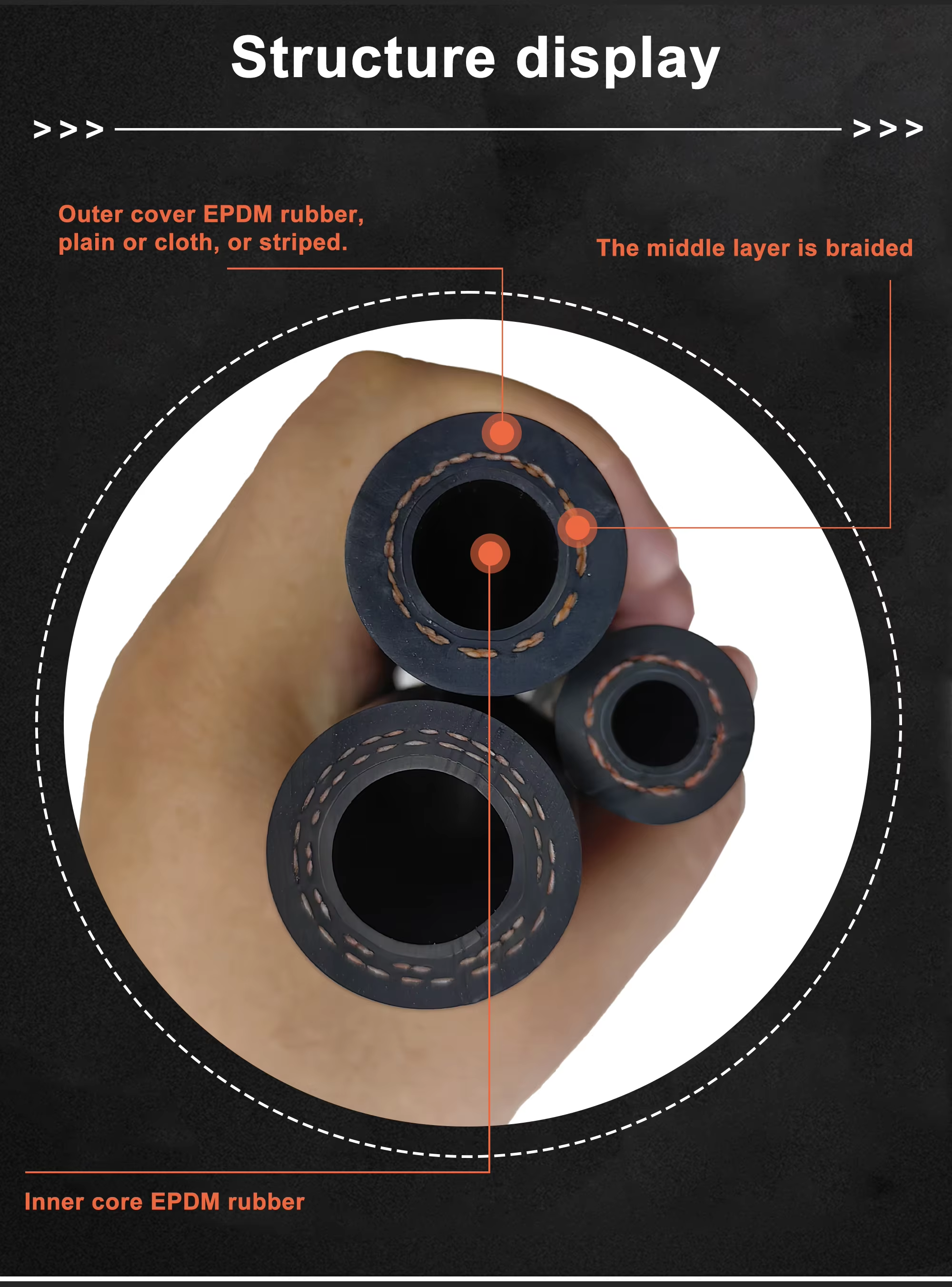

Brake hose assembly parts constitute complete ready-to-install components that integrate the flexible hose section with permanent end fittings through specialized crimping or swaging processes. These assemblies function as crucial connection elements between fixed brake lines and moving suspension components, maintaining hydraulic integrity while accommodating wheel movement and suspension articulation. The comprehensive assembly typically comprises the flexible hose section constructed from synthetic rubber or thermoplastic materials with embedded reinforcement layers, permanent end fittings manufactured from steel, brass, or aluminum alloys with specific thread configurations, and protective elements including rubber dust boots and mounting brackets. Engineering specifications address multiple performance parameters including minimum burst pressure ratings typically exceeding 8,000 PSI, impulse durability validation through 1-2 million pressure cycles at elevated temperatures, and flexibility requirements to withstand repeated bending without structural damage. Connection system variations include standard inverted flare fittings for domestic vehicles, metric bubble flare configurations for European applications, and O-ring face seal designs for specific truck and performance applications. Manufacturing processes involve precision cutting of hose materials to specific lengths, attachment of fittings using calibrated crimping equipment that applies predetermined compression forces, and 100% pressure testing to verify assembly integrity before packaging. A documented case from automotive manufacturers demonstrated how optimized assembly processes reduced failure rates by 75% during validation testing through improved crimping consistency and enhanced seal designs. Quality assurance protocols implement dimensional verification of all components, material certification from suppliers, and final validation through specialized testing including tensile strength measurement, extraction force verification, and environmental simulation. Installation considerations emphasize proper routing to avoid contact with moving components, correct positioning of mounting brackets to prevent stress concentration, and appropriate torque application during fitting installation. Our manufacturing capabilities include comprehensive assembly solutions for various vehicle categories with particular expertise in meeting original equipment specifications for dimensional accuracy and performance requirements. For detailed technical specifications and application information regarding brake hose assembly parts, we provide comprehensive documentation through our engineering resources and welcome specific technical inquiries.