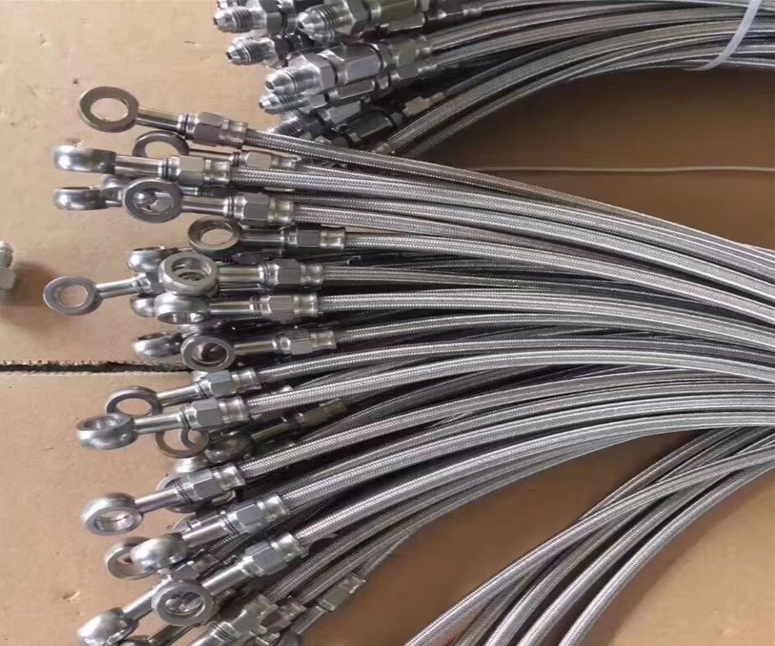

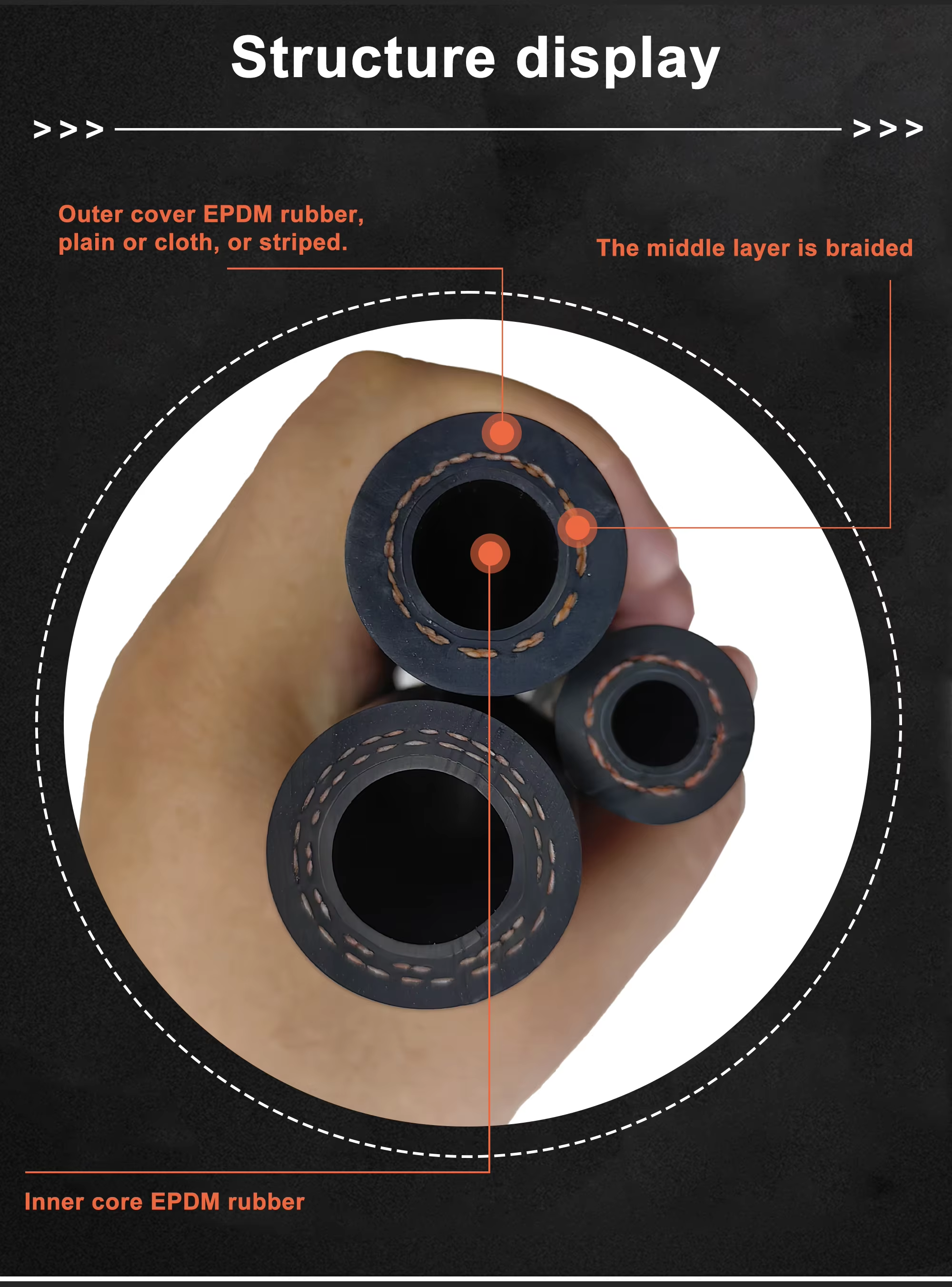

กระบวนการผลิตท่อเบรกเกี่ยวข้องกับการทำงานอย่างแม่นยำตามลำดับ ซึ่งเปลี่ยนวัตถุดิบให้กลายเป็นชิ้นส่วนที่สำคัญต่อความปลอดภัย โดยผ่านขั้นตอนการควบคุมที่เข้มงวดและมีการตรวจสอบคุณภาพอย่างละเอียด การผลิตเริ่มต้นจากการเตรียมวัสดุ ซึ่งรวมถึงการผสมยางสังเคราะห์ เช่น EPDM หรือ SBR เข้ากับสารเติมแต่งเฉพาะเพื่อเพิ่มความต้านทานของเหลวและความทนทานต่อสภาพแวดล้อม หรือการเตรียมสารประกอบเทอร์โมพลาสติก เช่น ไนลอน หรือ TPE ที่มีสมบัติทางกลเหมาะสม การอัดรูป (Extrusion) จะสร้างโครงสร้างพื้นฐานของท่อโดยใช้เครื่องจักรที่ควบคุมด้วยคอมพิวเตอร์ เพื่อรักษามาตรฐานขนาดเส้นผ่าศูนย์กลางภายในและแรงดันผนังอย่างแม่นยำ พร้อมระบบตรวจสอบแบบเรียลไทม์เพื่อให้มั่นใจในความสม่ำเสมอตลอดกระบวนการผลิต การเสริมความแข็งแรงใช้เครื่องทอเฉพาะทางที่ถักทอชั้นเส้นใยสังเคราะห์ความต้านทานแรงดึงสูง เช่น อราไมด์ หรือโพลีเอสเตอร์ หรือลวดสแตนเลส เป็นรูปแบบเฉพาะภายใต้แรงตึงที่ควบคุมได้ เพื่อให้ได้ความแข็งแรงของโครงสร้างพร้อมคงความยืดหยุ่นไว้ กระบวนการอบยาง (Vulcanization) สำหรับท่อแบบยางใช้ระบบหม้อต้มต่อเนื่อง (autoclave) หรือการขึ้นรูปแบบแยกชิ้น ซึ่งใช้อุณหภูมิเฉพาะระหว่าง 150℃-180℃ ภายใต้ความดัน เพื่อให้เกิดการเชื่อมโยงข้าม (cross-linking) อย่างเหมาะสมและได้สมบัติวัสดุที่ดีที่สุด ส่วนท่อเทอร์โมพลาสติกอาจต้องผ่านกระบวนการเพิ่มเติม เช่น การทำให้เกิดการเชื่อมโยงข้ามด้วยรังสีอิเล็กตรอน หรือวิธีทางเคมี เพื่อเพิ่มความต้านทานต่ออุณหภูมิและความทนทาน การตัดใช้อุปกรณ์อัตโนมัติที่มีความแม่นยำ เพื่อให้ปลายท่อมีหน้าตัดตรงและเรียบร้อย ซึ่งจำเป็นต่อการติดตั้งข้อต่ออย่างถูกต้อง พร้อมระบบตรวจสอบความยาวเพื่อให้มั่นใจว่าสอดคล้องกับค่าความคลาดเคลื่อนที่กำหนด การติดตั้งข้อต่อถือเป็นขั้นตอนสำคัญที่ใช้เครื่องอัดไฮดรอลิกที่มีแม่พิมพ์ปรับเทียบแล้ว ซึ่งใช้แรงอัดเฉพาะเพื่อสร้างการเชื่อมต่อถาวรระหว่างปลายท่อและข้อต่อโลหะ โดยระบบตรวจสอบกระบวนการจะบันทึกโปรไฟล์แรงอัดสำหรับการประกอบแต่ละชุด การทำเครื่องหมายใช้ระบบที่ทำให้เกิดเครื่องหมายถาวร เช่น รหัสผู้ผลิต วันที่ผลิต และเครื่องหมายรับรอง ด้วยล้อประทับหรือระบบเลเซอร์กัด การตรวจสอบขั้นสุดท้ายรวมถึงการทดสอบแรงดัน 100% การตรวจสอบด้วยสายตาเพื่อหาข้อบกพร่องบนพื้นผิว และการตรวจสอบมิติ พร้อมทั้งการสุ่มตัวอย่างเพื่อยืนยันคุณภาพอย่างครอบคลุม รวมถึงการทดสอบแรงกระแทกซ้ำๆ (impulse cycling) ความแข็งแรงดึง และความต้านทานต่อสิ่งแวดล้อม ปรัชญาการผลิตของเราเน้นการควบคุมกระบวนการและการพัฒนาอย่างต่อเนื่องผ่านเทคโนโลยีการผลิตขั้นสูงและระบบบริหารคุณภาพที่ครอบคลุม สำหรับข้อมูลโดยละเอียดเกี่ยวกับขีดความสามารถในการผลิตท่อเบรกและเทคโนโลยีกระบวนการของเรา เราขอเชิญชวนพันธมิตรที่สนใจปรึกษากับทีมวิศวกรรมของเราเพื่อรับเอกสารทางเทคนิคและการแนะนำภาพรวมโรงงาน