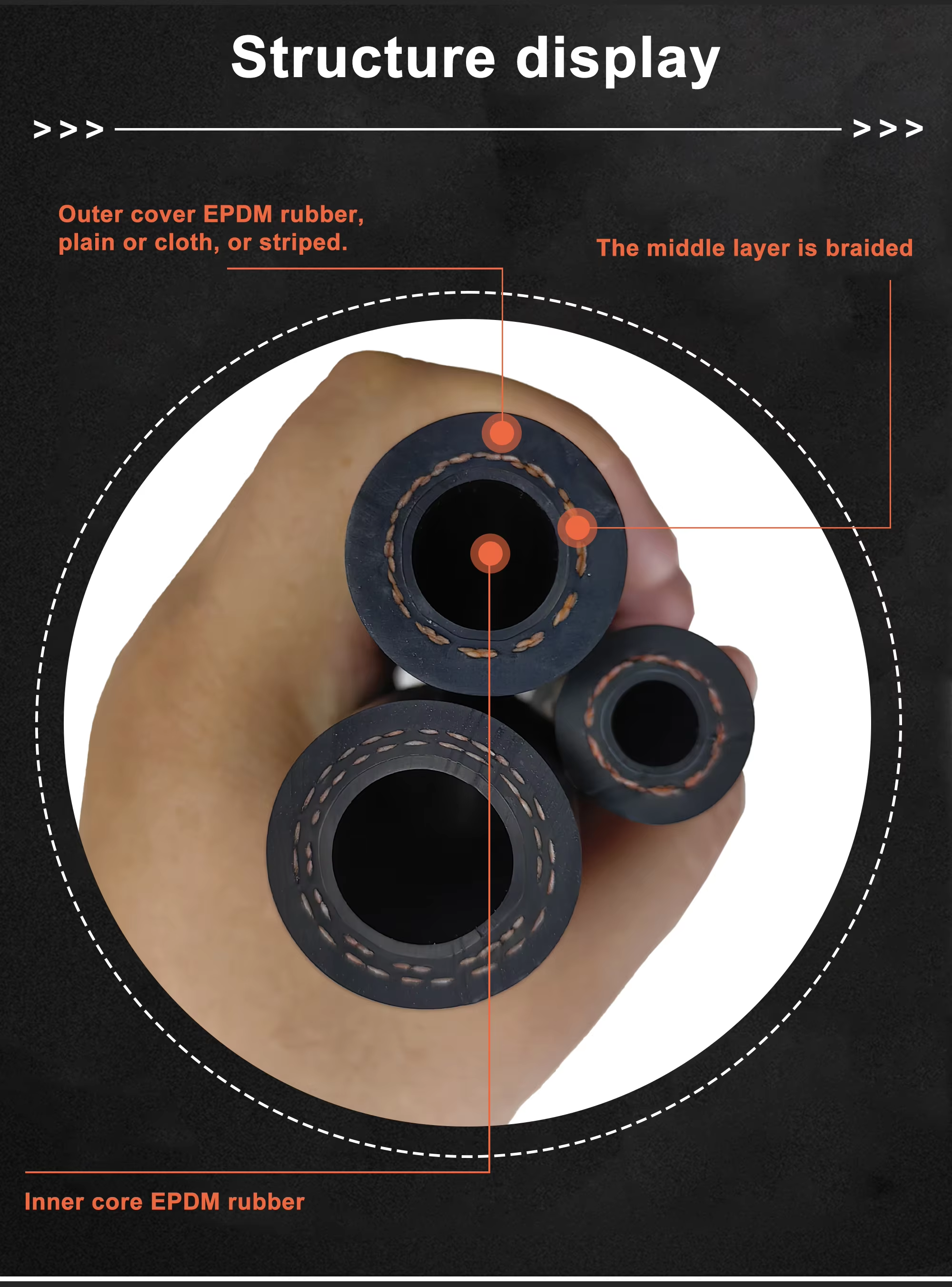

Brake hose safety standards establish a globally recognized framework of technical requirements and rigorous testing protocols designed to ensure the reliable performance and structural integrity of these critical automotive safety components under all anticipated operating conditions. These standards are not merely guidelines but are often legally mandated regulations that define the minimum performance thresholds a brake hose must meet to be deemed safe for road use. The international regulatory landscape is comprised of several key frameworks, including the United States Federal Motor Vehicle Safety Standard 106 (FMVSS 106), which provides detailed specifications for hydraulic brake hoses, the European Economic Commission Regulation ECE R13 and its subsequent series of amendments, which provide comprehensive type-approval requirements for braking components and systems, and various other national standards such as the Japanese JIS D2601 and Chinese GB standards. These foundational documents meticulously specify a suite of performance criteria. This includes minimum burst pressure requirements, which typically mandate that a hose must withstand an internal pressure of at least four times the system's normal working pressure without failure, ensuring a substantial safety margin. Impulse endurance testing is another critical requirement, subjecting the hose to a specified number of high-pressure cycles (often over a million) while immersed in heated brake fluid to simulate the long-term stress and thermal aging of years of service. Permeability tests are conducted to limit the loss of brake fluid vapor through the hose wall, which is crucial for maintaining system fluid volume and preventing air ingress. Dimensional tolerances for internal diameter, outer diameter, and fitting configurations are strictly controlled to ensure proper compatibility and sealing within the vehicle's brake system. The scope of testing extends far beyond these core requirements. Additional validation includes tensile strength tests to verify the hose can withstand stretching forces without separating from its end fittings, low and high-temperature flexibility assessments to ensure the hose does not become brittle in extreme cold or soften excessively in high underhood heat, and comprehensive compatibility testing with various brake fluids to prevent excessive swelling, softening, or degradation of the inner tube. Resistance to environmental factors is also critical, with ozone resistance testing conducted to prevent surface cracking of the outer cover, a common failure mode in modern urban atmospheres. The path to certification for a brake hose model is stringent. It typically involves submitting production-representative samples to an independent, accredited laboratory for formal type-approval testing against the relevant standard(s). This is followed by an audit of the manufacturer's factory production control (FPC) system to ensure consistent quality and ongoing conformity of mass-produced components. This conformity of production (CoP) is maintained through regular surveillance audits and periodic re-testing of samples taken from the production line. A documented case from the evolution of these standards demonstrated how updated material compatibility requirements, introduced to address new, more aggressive brake fluid formulations, directly led to a 22% reduction in field failure rates related to hose degradation. For a manufacturer, full compliance is embedded within a comprehensive Quality Management System, typically certified to IATF 16949, which enforces strict material traceability from raw compound to finished hose, detailed documentation of all process controls, and the meticulous maintenance of test records for every production batch. Our manufacturing processes are designed and controlled to fully comply with these international safety standards. This commitment is realized through rigorous raw material selection from approved suppliers, controlled and monitored production methods, and a comprehensive in-house testing regimen that is regularly validated by external certification bodies. For detailed information regarding our compliance with specific brake hose safety standards, access to certification documentation, or technical files for your regulatory submissions, our Quality Assurance department is prepared to provide comprehensive support and welcomes your specific inquiries.