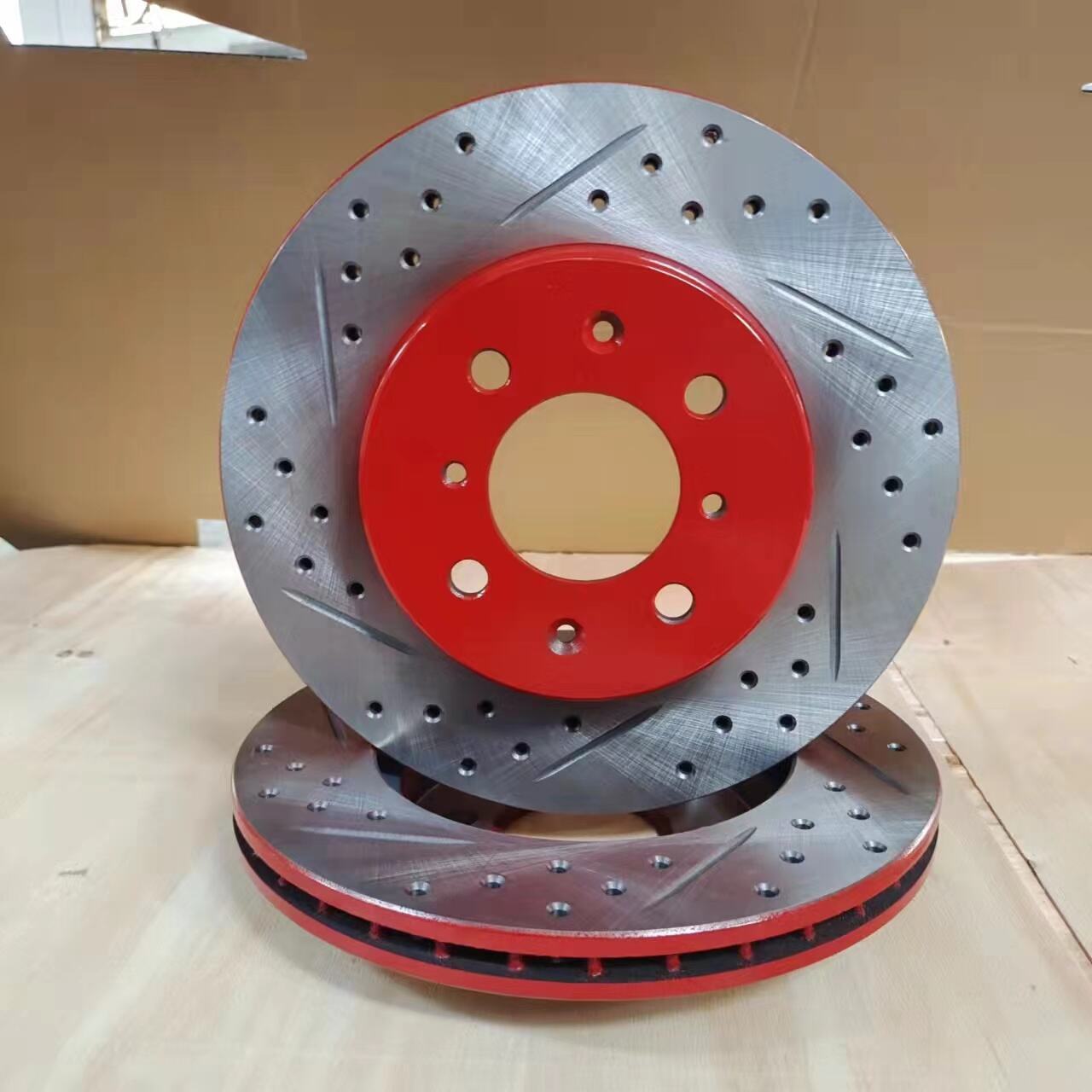

Drilled and slotted rotor discs constitute high-performance braking components that combine multiple functional advantages through strategic surface engineering. The drilled holes—typically arranged in specific patterns ranging from straight radial to curved or staggered configurations—serve primarily to vent gases generated between brake pads and rotor surfaces during extreme braking conditions, preventing the brake fade phenomenon known as "gas fade." Simultaneously, these holes facilitate water dispersal during wet weather operation, maintaining consistent friction levels when moisture might otherwise compromise braking effectiveness. The slots machined into the friction surface function as continuous cleaning mechanisms that scrape away pad glazing and remove debris from the contact interface, ensuring fresh friction material engagement while helping to manage combustion byproducts from organic brake pad formulations. Engineering considerations include careful calculation of hole placement to avoid stress concentration points, with chamfered edges to prevent crack propagation from thermal cycling. Performance testing demonstrates how drilled and slotted rotors can reduce braking distances by up to 15% in repeated high-temperature applications compared to plain rotors, while maintaining more stable friction coefficients throughout extended use. A documented case from performance driving schools shows how upgraded drilled and slotted rotors extended pad life by 25% during track day events where conventional rotors experienced accelerated wear from pad material transfer issues. Manufacturing processes require specialized equipment for precise hole drilling and slot machining after the initial casting and turning operations, with particular attention to maintaining structural integrity while creating these surface features. The design must balance the cooling benefits of additional surface area against the potential reduction in total friction surface, with optimal configurations typically featuring 48-72 holes and 12-24 slots depending on rotor diameter. Our product range includes various pattern options optimized for different driving conditions—from street performance applications with moderate hole densities to race-oriented designs with aggressive slot configurations. For technical specifications and application recommendations regarding drilled and slotted rotor discs, please consult our performance engineering team for detailed guidance on selection and installation procedures.