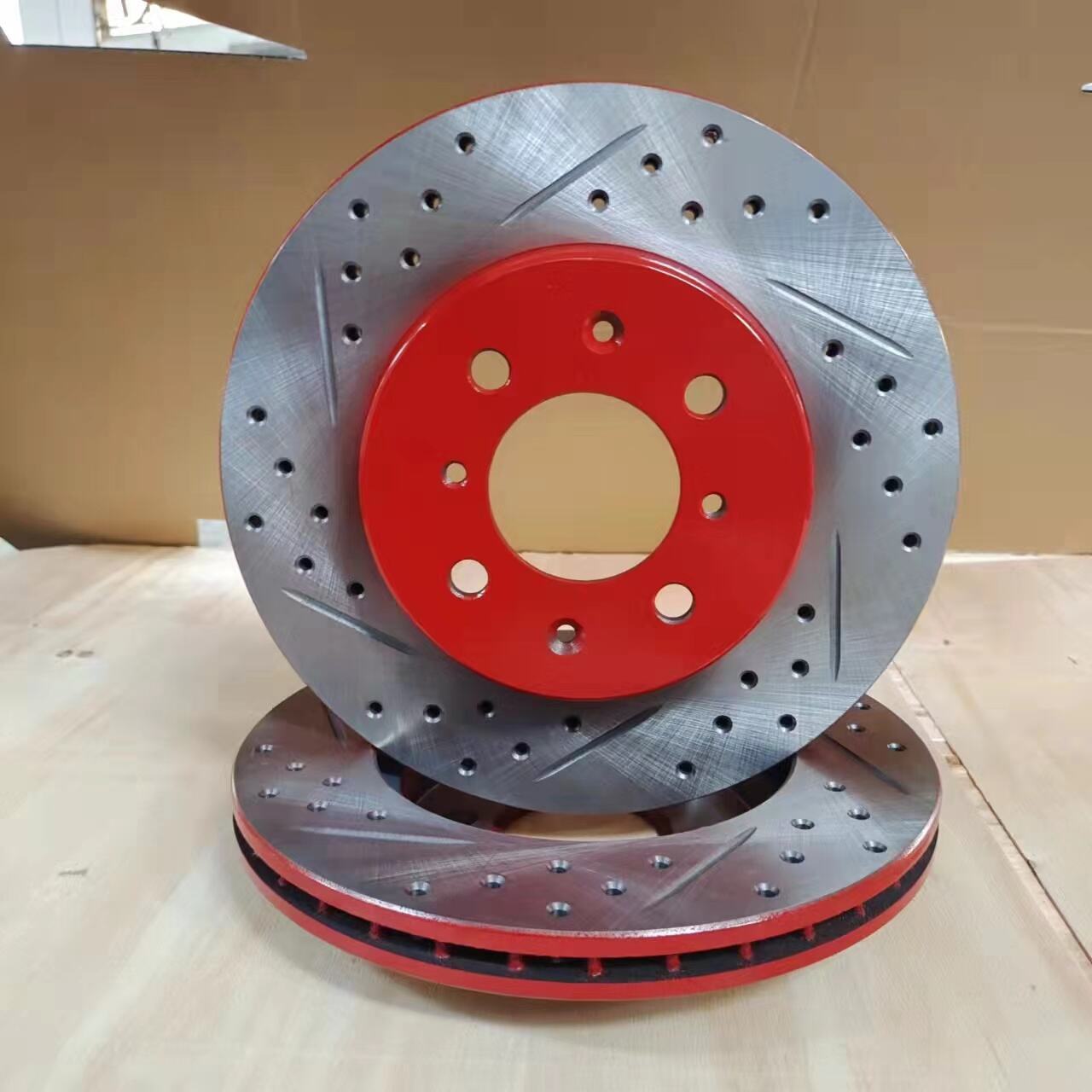

Coated drilled brake discs represent a premium braking solution that combines the performance advantages of drilled rotor designs with enhanced corrosion protection through specialized surface treatments. These components undergo a comprehensive manufacturing process that begins with high-quality iron casting followed by precision drilling operations that create specific hole patterns for gas venting and water dispersal. The coating application represents a critical secondary process where specialized materials—typically black geometric coating, zinc plating, or ceramic-based compounds—are applied to all non-friction surfaces through electrostatic deposition, thermal spraying, or electrochemical processes. The primary technical benefit involves exceptional resistance to environmental corrosion, particularly valuable for vehicles operated in coastal regions with salt-laden atmospheres or areas using de-icing chemicals during winter months. Performance testing demonstrates how the coating maintains adhesion and protective properties even when subjected to thermal cycling between -40°C and 500°C, with salt spray resistance exceeding 300 hours without base material corrosion. The drilled pattern typically features 48-72 strategically placed holes with chamfered edges to prevent crack propagation, while the coating must precisely cover all non-friction surfaces without encroaching on the braking tracks where it could compromise initial pad engagement. A documented case from North American markets shows how coated drilled rotors reduced corrosion-related comebacks by 60% in regions with severe winter conditions compared to uncoated alternatives. Application scenarios range from daily drivers seeking extended component life to performance vehicles where the combination of drilled functionality and corrosion resistance provides both practical and aesthetic benefits. Installation protocols emphasize proper handling to prevent damage to the coated surfaces, with specific procedures for initial bedding to establish proper transfer layers on the uncoated friction surfaces. Our manufacturing capabilities include multiple coating options with varying thicknesses and color alternatives to meet different market preferences and environmental requirements. For technical specifications and application recommendations regarding coated drilled brake discs, please contact our engineering team for detailed product information and customization possibilities based on specific vehicle applications and operating conditions.