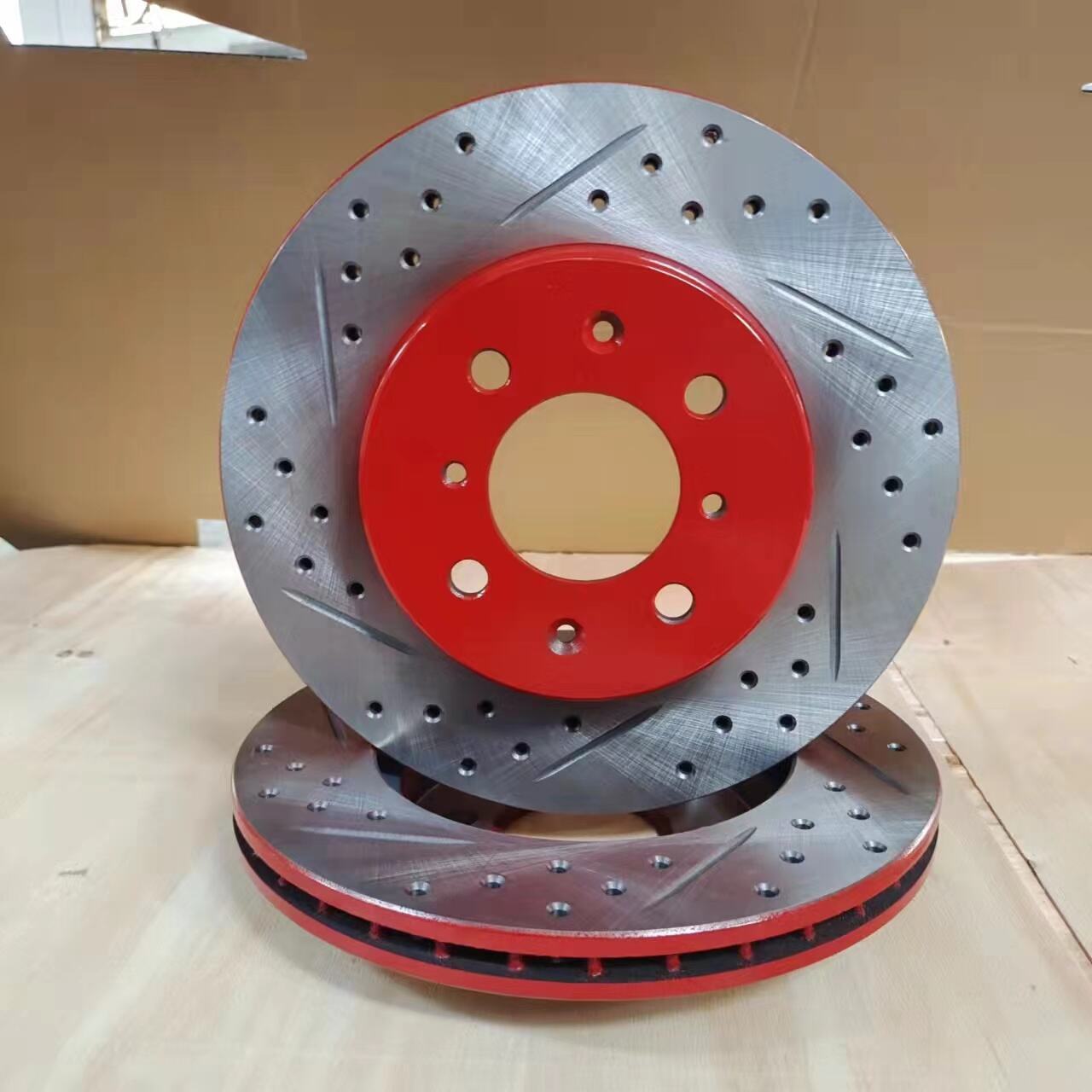

دیسکهای روتور سوراخدار و شیاردار، اجزای ترمز با عملکرد بالا محسوب میشوند که از طریق مهندسی سطحی هدفمند، چندین مزیت عملکردی را با یکدیگر ترکیب میکنند. سوراخهای ایجادشده — که معمولاً در الگوهای خاصی از حالت شعاعی مستقیم تا پیکربندیهای منحنی یا متقارن قرار گرفتهاند — عمدتاً برای تخلیه گازهای تولیدشده بین لنت ترمز و سطح روتور در شرایط ترمز شدید به کار میروند و از پدیده کاهش عملکرد ترمز (به اصطلاح "کاهش ناشی از گاز") جلوگیری میکنند. همزمان، این سوراخها در شرایط بارانی به پراکندن آب کمک کرده و سطح اصطکاک را ثابت نگه میدارند، زمانی که حضور رطوبت ممکن است عملکرد ترمز را تحت تأثیر قرار دهد. شیارهای ماشینکاریشده روی سطح اصطکاک، به عنوان مکانیسمهای تمیزکنندهٔ مداوم عمل میکنند که از سوختگی سطح لنت جلوگیری کرده و ذرات آلاینده را از محل تماس بیرون میزنند و اطمینان حاکم میشود که مواد اصطکاکی تازه درگیر شوند، در عین حال به مدیریت محصولات جانبی احتراق ناشی از فرمولاسیونهای لنت ترمز آلی کمک میکنند. ملاحظات مهندسی شامل محاسبه دقیق محل قرارگیری سوراخها جهت جلوگیری از نقاط تمرکز تنش است، بهطوری که لبههای فرزشده (Chamfered) از ایجاد ترک در اثر چرخههای حرارتی جلوگیری میکنند. آزمایشهای عملکردی نشان میدهند که روتورهای سوراخدار و شیاردار در کاربردهای مکرر با دمای بالا، فاصله ترمزگیری را تا ۱۵٪ نسبت به روتورهای ساده کاهش میدهند و در عین حال ضریب اصطکاک پایدارتری در طول استفاده مداوم حفظ میکنند. یک مورد ثبتشده از مدارس رانندگی عملیاتی نشان میدهد که استفاده از روتورهای ارتقاءیافتهٔ سوراخدار و شیاردار، عمر لنتها را در رویدادهای مسابقهای (Track Day) تا ۲۵٪ افزایش داده است، در حالی که روتورهای معمولی به دلیل مشکلات انتقال مواد لنت، سایش تسریعشدهای را تجربه میکردند. فرآیندهای تولید به تجهیزات تخصصی برای انجام دقیق سوراخکاری و ماشینکاری شیار پس از عملیات اولیه ریختهگری و پرداخت نیاز دارند و توجه ویژهای به حفظ یکپارچگی ساختاری در هنگام ایجاد این ویژگیهای سطحی میشود. طراحی باید مزیتهای خنککنندگی ناشی از افزایش سطح با امکان کاهش کل سطح اصطکاک را متعادل کند، بهطوری که پیکربندیهای بهینه معمولاً شامل ۴۸ تا ۷۲ سوراخ و ۱۲ تا ۲۴ شیار هستند که بسته به قطر روتور متفاوت است. محدوده محصولات ما شامل گزینههای مختلفی از الگوهاست که برای شرایط رانندگی متفاوت بهینهسازی شدهاند — از کاربردهای عملکردی شهری با چگالی متوسط سوراخ تا طرحهای مسابقهای با پیکربندی شیارهای تهاجمی. برای مشخصات فنی و توصیههای کاربردی در مورد دیسکهای روتور سوراخدار و شیاردار، لطفاً با تیم مهندسی عملکرد ما مشورت کنید تا راهنمایی دقیقی در مورد انتخاب و رویههای نصب دریافت نمایید.