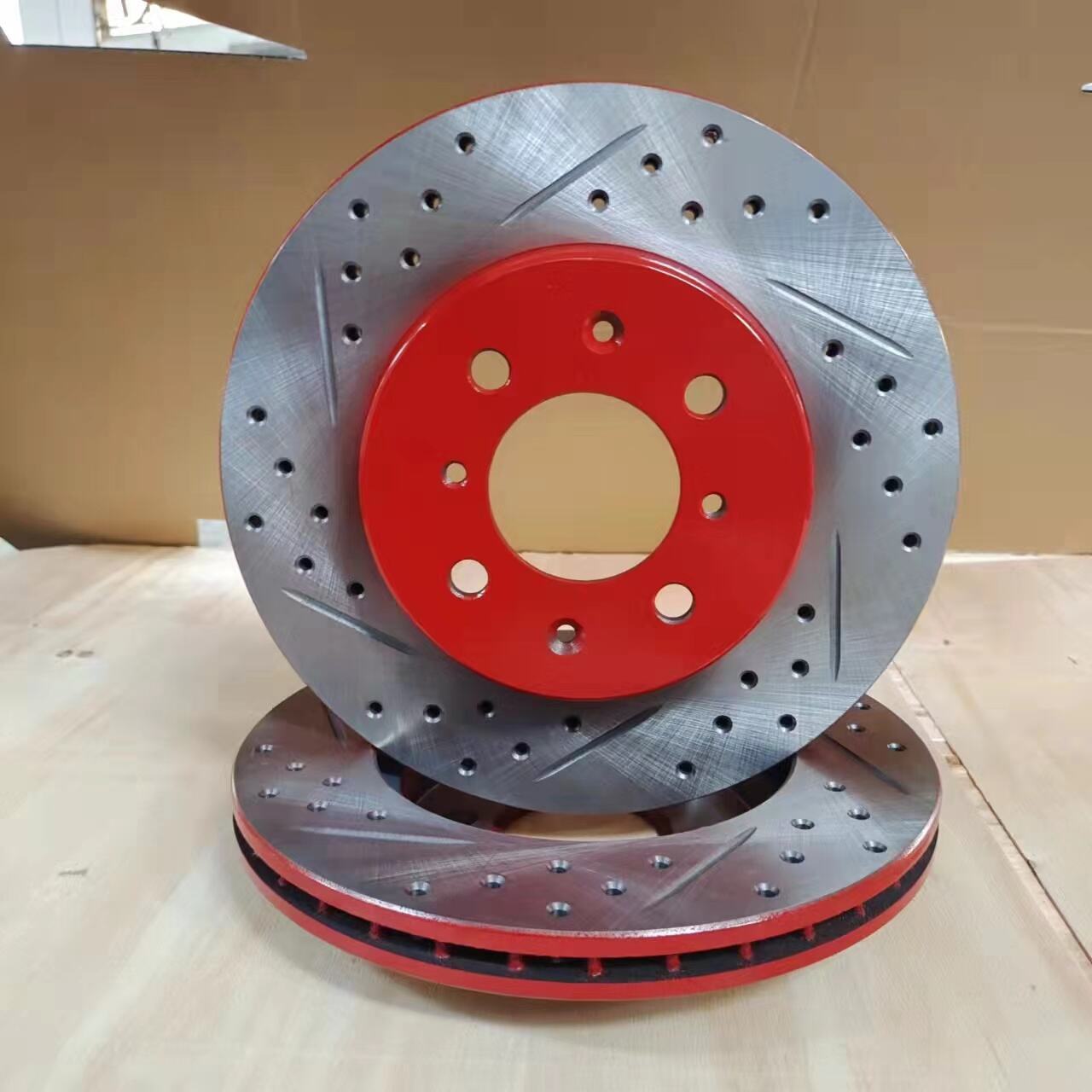

High quality brake discs represent precision-engineered safety components that exceed fundamental functional requirements through superior materials, manufacturing processes, and performance validation. The quality foundation begins with metallurgical composition utilizing high-carbon gray iron alloys with controlled carbon equivalents between 3.5-4.0%, supplemented with chromium, molybdenum, and nickel additions that enhance thermal conductivity, wear resistance, and structural stability. Manufacturing excellence involves automated precision casting with controlled cooling rates that prevent internal stresses and ensure uniform pearlitic microstructure throughout the component. Machining operations maintain dimensional tolerances within 0.005mm for critical parameters including thickness variation, parallelism, and flatness, while dynamic balancing ensures vibration-free operation at all vehicle speeds. Performance validation includes rigorous testing on inertia dynamometers simulating extreme conditions—from repeated stops from high speeds that generate temperatures exceeding 600°C to simulated mountain descent scenarios with sustained braking application. A documented case from European certification agencies demonstrates how premium brake discs maintained consistent friction coefficients after 300 consecutive high-temperature stops, while economy alternatives experienced performance degradation after just 50 similar cycles. Quality assurance protocols implement statistical process control at each manufacturing stage, with comprehensive material certification tracing back to raw material sources. The product range includes various design optimizations—directional vane patterns for enhanced cooling efficiency, reinforced hat sections for heavy-duty applications, and specialized surface treatments for corrosion protection. Application scenarios span from original equipment specifications for automotive manufacturers to replacement markets where consumers seek extended service life and consistent performance. Our manufacturing philosophy emphasizes continuous improvement through research into advanced materials including compacted graphite iron and developing proprietary manufacturing techniques that enhance product longevity. For comprehensive information regarding our high quality brake disc specifications and performance data, we provide detailed technical documentation and application guidance through our engineering support services.