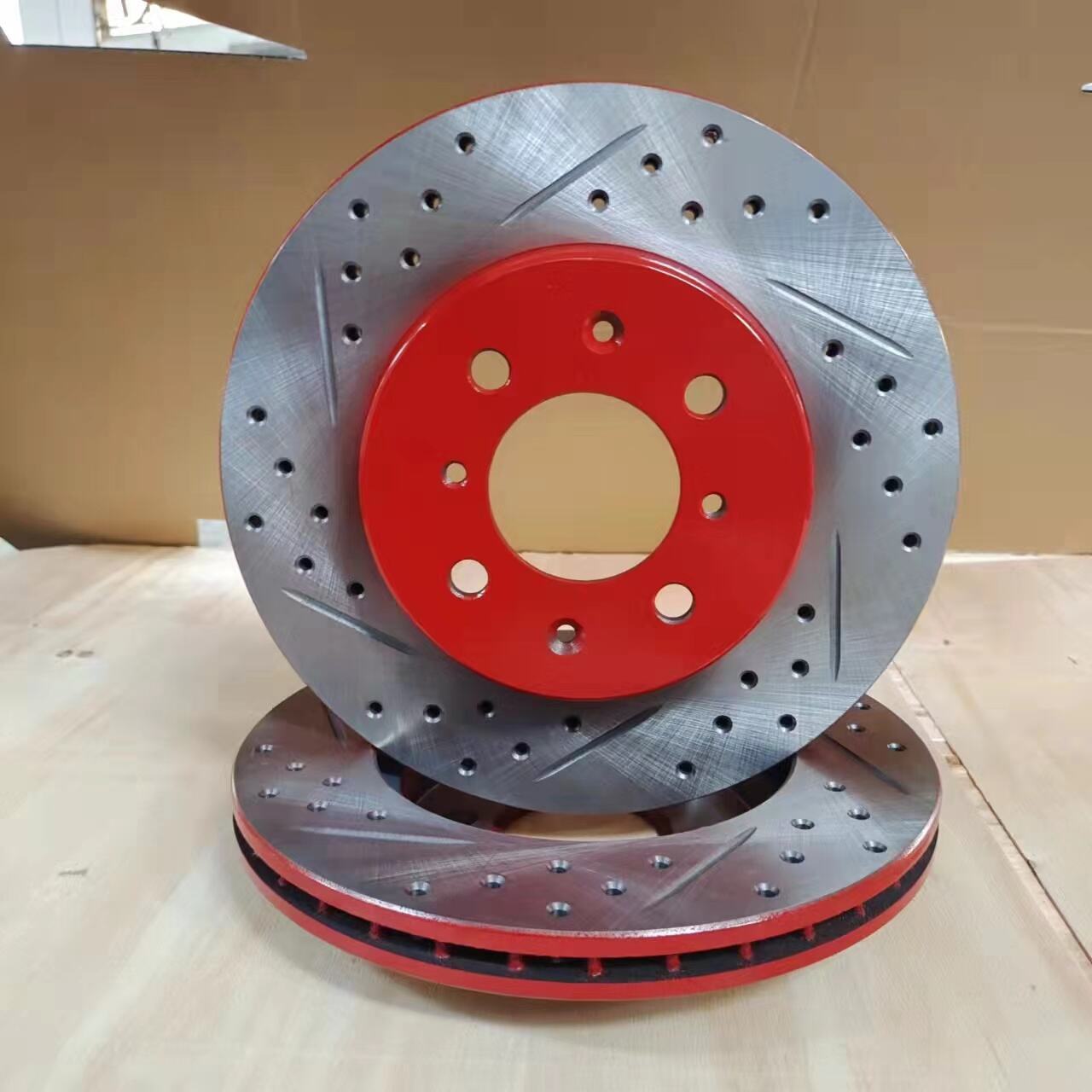

Brake discs, also called rotors, are vital rotating components within automotive braking systems that provide the friction surface against brake pads to convert kinetic energy into thermal energy through friction, thereby enabling vehicle deceleration. These components are predominantly manufactured from high-carbon cast iron alloys with controlled pearlitic microstructure and graphite distribution, engineered to deliver consistent friction characteristics, efficient heat dissipation, and structural integrity under extreme mechanical and thermal loads. The fundamental operating principle involves clamped friction between stationary brake pads and the rotating disc surface, generating temperatures that can exceed 500掳C during normal operation and reaching 700掳C or higher during severe braking events. Design variations include solid discs for economy applications, vented rotors with internal radial vanes for enhanced cooling capacity in medium-duty vehicles, and directional vane designs that optimize airflow efficiency for high-performance applications. Performance parameters encompass thermal capacity for heat absorption and dissipation, structural strength to withstand mechanical stresses, wear resistance for extended service life, and consistent friction characteristics across operating temperature ranges. Technical specifications include minimum thickness values stamped on the disc hub, typically 1.5-2.0mm less than new thickness, maximum runout limits generally below 0.05mm to prevent vibration, and strict parallelism requirements within 0.005mm to ensure uniform pad contact. A documented case from automotive engineering demonstrates how advanced brake disc designs reduced stopping distances by 12% in wet conditions through optimized surface water dispersal patterns compared to conventional designs. Manufacturing processes involve precision casting with controlled cooling rates to ensure uniform metallurgical structure, followed by computer-numerical-control machining that maintains critical dimensional tolerances, and often include specialized surface treatments for corrosion protection. Application engineering addresses specific vehicle requirements including compatibility with electronic stability control systems, weight optimization for unsprung mass reduction, and specialized designs for electric vehicles with blended regenerative braking. Our product development focuses on advancing brake disc technology through material innovations, cooling efficiency improvements, and application-specific solutions for evolving automotive platforms. For comprehensive technical information regarding brake disc specifications, selection guidelines, and performance characteristics, we provide detailed engineering documentation through our technical support services.