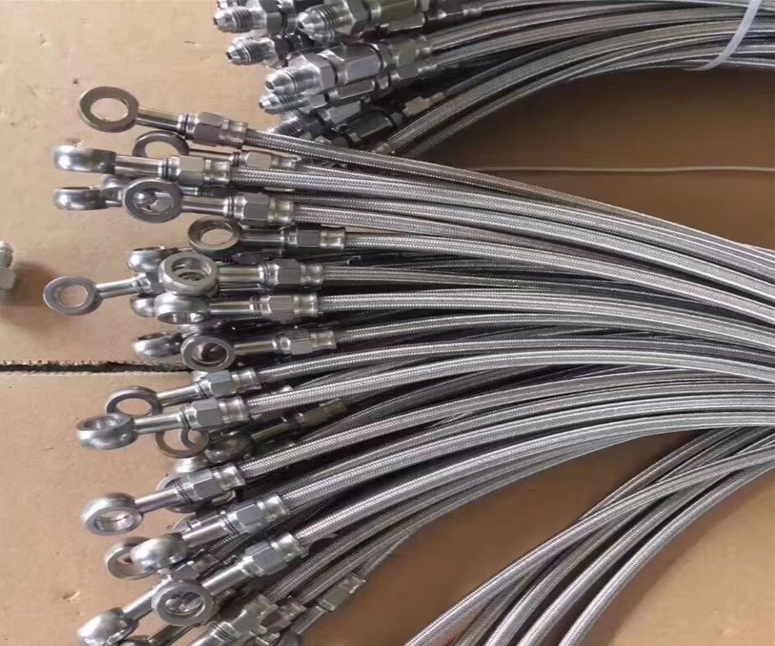

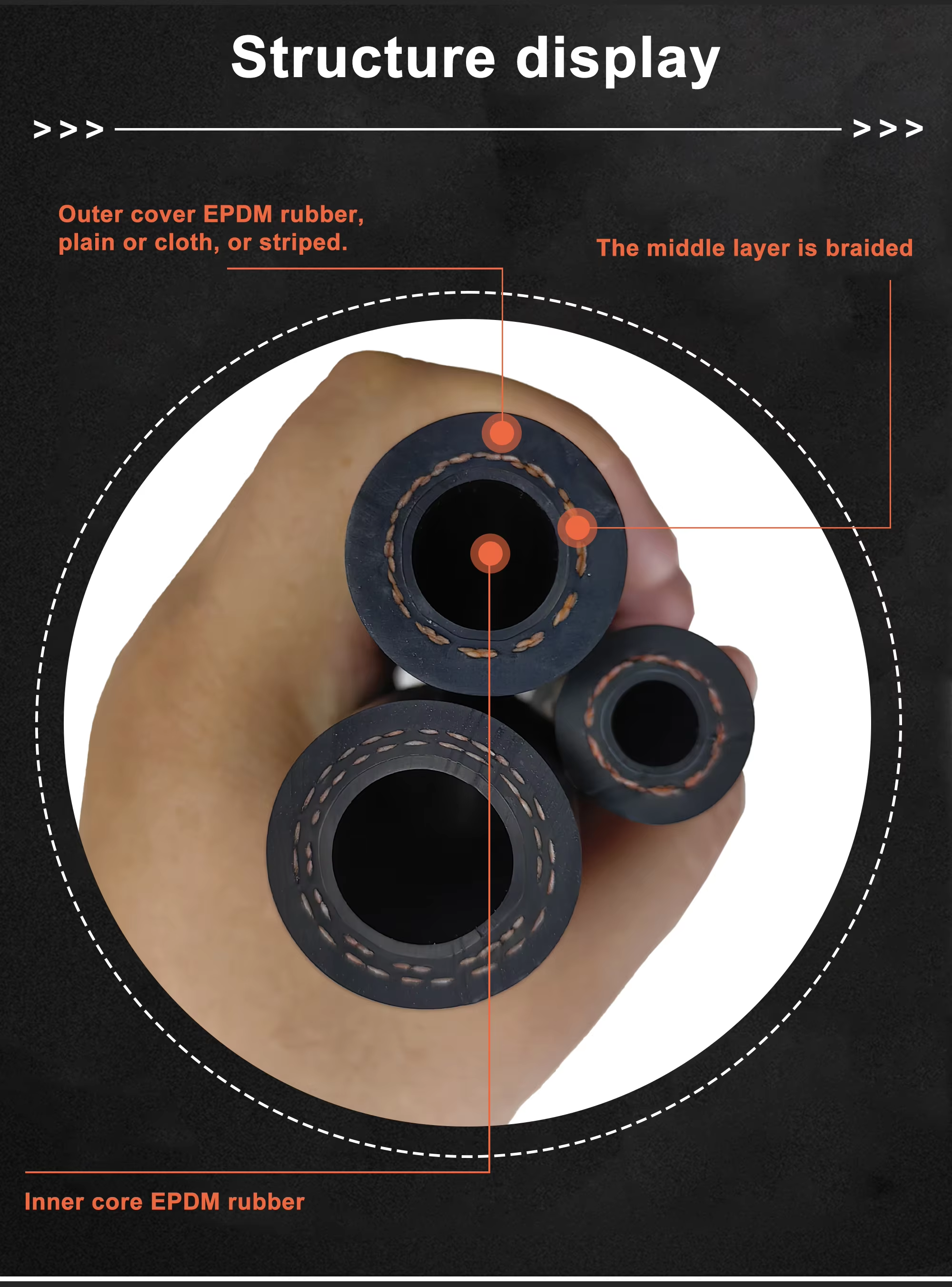

Custom brake hose solutions encompass specialized engineering services dedicated to developing application-specific braking system components that precisely address unique vehicle requirements, performance objectives, or operating conditions beyond the scope of standard production offerings. These bespoke projects are initiated with a comprehensive requirements analysis phase, meticulously gathering data on vehicle parameters, specific performance targets, environmental operating conditions, connection specifications, and all relevant regulatory compliance mandates. The subsequent engineering development process leverages advanced computational analysis, including Finite Element Analysis (FEA) to simulate stress distribution under high-pressure cycling conditions, computational fluid dynamics (CFD) for optimizing flow characteristics and minimizing pressure drop, and rigorous material compatibility validation with various brake fluids (DOT 3, DOT 4, DOT 5.1) and extreme environmental exposures. The spectrum of customization is vast, ranging from modified existing production designs—involving specific length adjustments, bespoke fitting configurations, or alternative mounting brackets—to completely new developments that incorporate innovative materials, unique reinforcement patterns, or novel connection systems. Material selection is a critical facet of the process, potentially involving specialized synthetic rubber compounds formulated for enhanced high-temperature resistance, advanced thermoplastic formulations that offer superior reduced permeability, or custom reinforcement layers utilizing high-tensile synthetic yarns like aramid or precisely engineered stainless steel braiding to meet specific burst pressure requirements. A documented case study from a motorsport application powerfully demonstrates the potential of these solutions, where a custom brake hose design achieved a 35% reduction in weight while simultaneously withstanding operational pressures exceeding 3,000 PSI in a racing prototype, thereby achieving critical performance targets that were entirely unavailable through standard, off-the-shelf components. The manufacturing capabilities supporting these custom solutions are equally specialized, featuring flexible production lines capable of handling various hose diameters, specialized crimping and swaging equipment calibrated for different fitting types and materials, and dedicated testing apparatus for validation under extreme conditions. Performance validation adheres to project-specific protocols, which may include intensive impulse testing exceeding 1 million cycles to simulate long-term durability, extreme temperature exposure testing from -50°C to 150°C to ensure functionality in harsh climates, and comprehensive compatibility testing with various braking fluids and environmental contaminants like road salts and oils. Typical application scenarios for these engineered solutions are diverse, including classic car restoration projects requiring accurate reproduction of discontinued parts, motorsport vehicles with unique packaging constraints and extreme performance demands, military vehicles operating in the world's most extreme and unpredictable environments, and prototype vehicles involved in developing next-generation braking system concepts. Our engineering philosophy is fundamentally collaborative, emphasizing continuous customer involvement and transparent communication throughout the entire iterative process, from the initial design concepts and prototyping phases to the final validation and production stages. For comprehensive information regarding our custom brake hose solutions and specialized engineering services, we invite vehicle manufacturers, racing teams, and specialty equipment providers to consult directly with our engineering division for a detailed project evaluation and the development of a formal proposal.