The Critical Role of Brake Discs in Commercial Vehicle Safety

Brake disc integrity is fundamental to commercial vehicle safety, where even minor defects can lead to critical system failures. According to the NHTSA (2023), brake system issues contribute to 40% of truck-related accidents, highlighting the necessity for precision-engineered components in heavy-duty operations.

Why Brake Disc Quality Directly Impacts Truck Safety

Quality brake discs can handle temperatures over 1,200 degrees Fahrenheit when stopping suddenly without bending out of shape, which helps stop the brakes from losing effectiveness. Tests on mechanical wear indicate that cheaply made discs tend to crack much quicker under heavy pressure. These cracks happen about three quarters faster than they should, making cars take longer to stop completely and raising the chance of dangerous jackknifing situations. When it comes to heat resistance, top quality discs keep their grip at around 90% throughout multiple intense braking episodes, whereas cheaper options drop down to roughly two thirds of that performance level after repeated use. This difference really matters for safety on the road.

How Reliable Brake Discs Support Driver Control and Accident Prevention

Discs that are precision machined give calipers millimeter accuracy when engaging, so drivers can really control how much braking power they apply in those emergency stop scenarios or when roads get slick. When trying to avoid collisions, ventilated discs actually slow things down about 15 percent quicker compared to regular solid rotors because they dissipate heat better. And this makes all the difference. According to recent FMCSA numbers from last year, nearly half again as many truck accidents happen on highways simply because brakes didn't respond fast enough.

Brake Disc Performance Under High Stress and Thermal Load

Brake discs used in commercial vehicles face serious thermal and mechanical stress when they get pushed hard, especially during sudden stops where temps can hit over 650 degrees Celsius or around 1,200 Fahrenheit. For these harsh conditions, manufacturers need materials that can stand up to intense heat without losing their strength. According to tests on thermal stress, high carbon alloy discs maintain about 92 percent of their friction properties even at 550 degrees Celsius. Meanwhile regular cast iron discs drop down to just 65 percent effectiveness at those same temperatures, making them much less reliable for heavy duty applications.

Heat Resistance and Durability of Brake Discs in Long-Haul Operations

The heat stress on long haul trucks amounts to roughly 7,500 complete stops every year according to industry estimates. New materials such as boron treated cast iron can actually double the lifespan of components compared to traditional options, as shown in recent research from Yin and colleagues back in 2023. Meanwhile truck manufacturers are turning to laser clad coatings that cut down thermal cracking problems by about two thirds when operating in extreme conditions like desert transport routes where temperatures soar. Many original equipment manufacturers now specify dual phase steel cores combined with ceramic composites because these materials handle heat much better than older alternatives. They conduct heat at around 160 watts per meter kelvin and maintain structural integrity even under pressures exceeding 450 megapascals, making them ideal for heavy duty applications where reliability matters most.

Ventilated Brake Discs and Their Role in Efficient Heat Dissipation

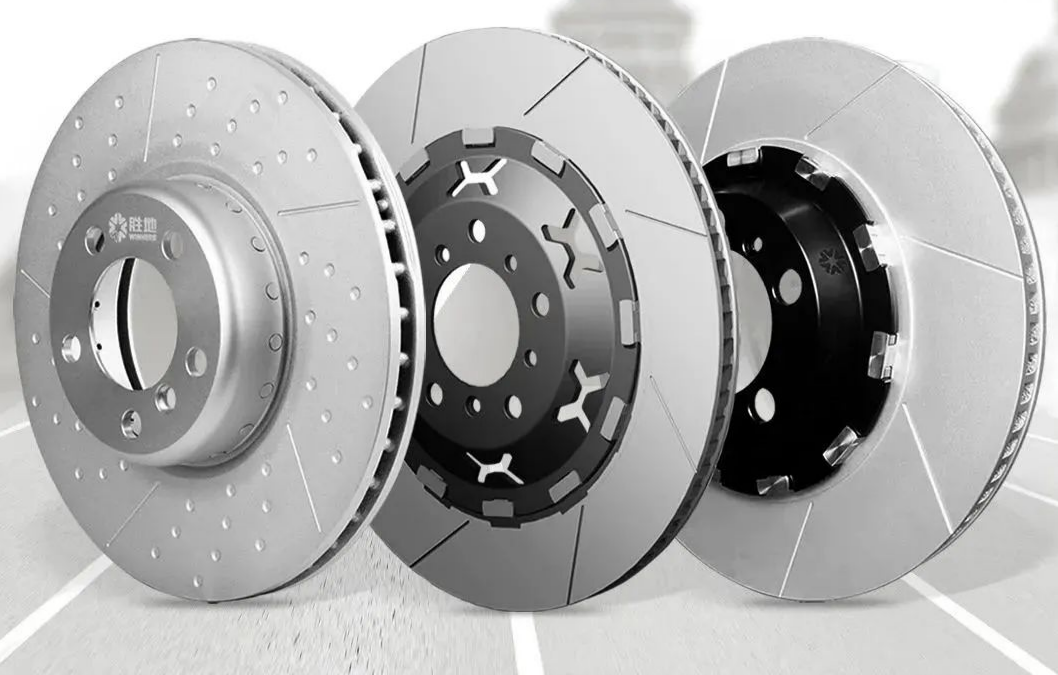

Cross-drilled and slotted ventilated discs lower peak rotor temperatures by 15–20% through improved airflow. A 2024 ventilation efficiency study demonstrated that asymmetric vane angles enhance convective cooling by 34% over traditional radial designs. This advancement enables 22% faster cooldown between repeated brake applications, a critical advantage in mountainous terrain.

Preventing Brake Fade Through Advanced Disc Materials and Design

Discs made from carbon reinforced silicon carbide (C\/SiC) cut down on brake fade problems by about half when vehicles are braking continuously at speeds around 85 km\/h. According to finite element analysis studies, wave lock rotor mounts actually cut thermal deformation down roughly 28 percent better than traditional fixed caliper setups. Real world testing has demonstrated that ceramic coated discs keep their grip strength above 0.38 even after making fifteen intense stops in succession. This kind of performance matters a lot for heavy duty applications like tanker trucks carrying dangerous goods where consistent stopping power is absolutely critical safety requirement.

Shorter Stopping Distances with High-Performance Brake Discs

How Superior Brake Disc Performance Reduces Stopping Distance

Better quality brake discs help vehicles stop faster because they have improved friction surfaces and handle heat much better. When tested alongside ceramic brake pads, these high end discs actually cut down stopping distance by around 50 feet at speeds of 100 miles per hour compared to regular brakes. That makes a huge difference in safety situations. For big trucks carrying heavy loads, this extra stopping power matters even more since loaded vehicles need about 40 percent greater braking force than when they're empty on the road.

Emergency Braking Scenarios: The Safety Advantage of Air Disc Brakes

When it comes to stopping power, air disc brakes really beat old school drum systems during emergencies, often surpassing what the government requires by around 16 percent. The difference is huge too – these discs can cut stopping distance by about 20 feet when going 60 miles per hour. That kind of margin matters a lot when trying to dodge something unexpected on the road. Regular drum brakes tend to lose their grip after getting hot from constant use, but air disc setups keep working reliably even after multiple hard stops. Drivers who have switched report feeling much more confident knowing their brakes won't fade away when they need them most.

Case Study: Measurable Improvements in Stopping Distance with Advanced Brake Discs

A 12-month fleet trial compared 200 trucks equipped with ventilated carbon-composite discs against those using conventional iron discs:

| Metric | Carbon Discs | Iron Discs | Improvement |

|---|---|---|---|

| Avg. stopping distance (60 MPH) | 210 feet | 240 feet | 12.5% |

| Brake fade incidents | 3 | 27 | 89% reduction |

These results demonstrate how material innovation translates into measurable safety improvements, particularly in demanding environments like mountainous routes.

Ensuring Balanced Braking and Preventing Brake Pull

How Uniform Brake Disc Wear Contributes to Symmetrical Braking

When brake pads wear evenly across their surface, they distribute friction more uniformly, which helps keep vehicles stable when stopping suddenly. Research from the National Transportation Safety Board back in 2022 showed something interesting about truck brakes. They discovered that discs that wore unevenly caused problems with side-to-side balance, increasing lateral forces by nearly 40% in big rigs. This imbalance was linked to about a 22% greater chance of experiencing brake pull where one side stops faster than the other. Today's advanced manufacturing methods have really improved things though. Techniques like laser guided rotor machining can produce parts with thickness differences under 0.003 inches. Getting this kind of precision matters because it keeps braking forces balanced across all wheels.

Brake Pull Prevention Through Proper Alignment and Disc Integrity

Brake pull typically results from misaligned calipers or compromised disc surfaces. Trucks undergoing quarterly brake inspections experience 63% fewer alignment-related pull incidents than those inspected annually. Best practices in maintenance now include:

- Torque verification of wheel-end components during tire rotations

- Thermal imaging to detect hotspots indicative of warping

- 3D surface profilometry for wear pattern analysis

These methods help maintain disc flatness within 0.0005 inches under operating temperatures, effectively minimizing lateral forces during emergency stops.

Proactive Maintenance for Long-Term Brake Disc Reliability

Essential Brake Maintenance Protocols to Preserve Disc Performance

Getting regular checkups around the 10k to 15k km mark helps spot problems before they get serious, like when brakes start wearing unevenly or developing those tiny cracks we don't notice right away. What mechanics typically do is measure how thick the rotors still are according to what the car maker says, give everything a good clean so dirt doesn't cause extra wear, and swap out old brake fluid roughly every two years since it tends to pick up moisture over time which can eat away at metal parts. When looking at disc temperatures through thermal imaging, anything running hotter than about 650 degrees Celsius puts them in real danger of warping. Studies indicate that sticking to these regular inspections cuts down on that particular problem by nearly three quarters compared to waiting until something breaks down first.

Predictive Maintenance Trends: Smart Sensors in Modern Brake Discs

IoT-enabled sensors now monitor real-time temperature, vibration, and wear in commercial brake systems. These devices provide:

- Early alerts for thickness loss (down to 0.5mm thresholds)

- Dynamic heat mapping to identify abnormal friction zones

- Automated service notifications integrated with fleet management platforms

Field trials show sensor-equipped brake discs reduce unplanned downtime by 41% and extend component life by 25–30%. By combining scheduled maintenance with predictive analytics, fleets achieve greater safety and operational efficiency.

FAQ

Why is brake disc quality crucial for truck safety?

High-quality brake discs handle extreme temperatures and pressures without failing, reducing the risk of accidents due to brake fade or failure.

What types of brake discs are most effective under high stress?

High carbon alloy and ventilated discs are more effective as they maintain friction and cooling properties under heavy stress and thermal loads.

How do ventilated brake discs help with heat dissipation?

Ventilated discs improve airflow, reducing peak temperatures by 15-20%, which leads to faster cooldown times, particularly useful in mountainous driving.

What maintenance practices ensure brake disc reliability?

Regular inspections, thermal imaging for heat spots, and ensuring proper alignment help maintain brake disc integrity and prevent brake pull.

How do advanced materials reduce stopping distances?

Advanced materials improve friction and heat management, significantly reducing stopping distances, which enhances vehicle safety.